METTLER-TOLEDO PRODUCT INSPECTION

The product inspection division of METTLER TOLEDO produces high quality, very reliable inspection equipment for use in high speed, demanding manufacturing production lines. Our checkweighers complete a 100% weight check of all items, while our metal detectors ensure that any metal contamination is found and eliminated from the production line. Additionally, x-ray inspection systems are able to effectively detect dense physical contaminants as well as measure mass and check for missing or damaged product inside closed packages, and our vision inspection systems automatically check the product to ensure perfect presentation and that all required markings are present.

CONTACT INFORMATION

Mettler-Toledo Product Inspection

1571 Northpointe Parkway

Lutz, FL 33558

UNITED STATES

FEATURED ARTICLES

-

Mettler-Toledo Product Inspection Group will demonstrate a variety of inspection equipment for the commercial baking industry at IBIE, being held at the Las Vegas Convention Center, Sept. 14-17, 2025. Located at booth 2473 in the West Hall, the company will present solutions that help processors of baked goods improve food safety, enhance product quality and optimize production efficiencies while addressing evolving market demands and regulatory requirements.

-

With operational costs rising and production line efficiency under pressure, manufacturers need to be confident that any new equipment investment will deliver value. Mettler-Toledo Product Inspection’s Test Before You Invest program is designed to help food, pharmaceutical and packaging manufacturers make informed product inspection choices through hands-on testing, real performance data and expert support.

-

Wellington Foods ensures dietary supplement safety using METTLER TOLEDO’s X37 X-ray system, which detects contaminants, and meets regulatory standards with high-speed, precise inspection technology.

-

Learn how Fiasco Gelato ensures contaminant-free products with an inspection system, enhancing food safety and supporting their expansion goals.

-

Following the successful launch of the X2 Series of x-ray inspection systems, Mettler-Toledo Product Inspection is proud to introduce the new X6 Series, offering a significant product safety upgrade for medium to large-sized packaged products and multi-lane applications. The X6 Series consisting of the X16 and X36.2 x-ray inspection systems presents a range of new features that provide precise contamination detection across single or multiple lanes. Both solutions can inspect medium to large-sized products (500-600mm in length) while also maximizing productivity through easy-to-use design improvements.

-

Mettler-Toledo Product Inspection Group will present a variety of inspection systems in booth S-2939 at Pack Expo, being held at the McCormick Place in Chicago, November 3 – 6, 2024. New combination systems, x-ray inspection systems and more will be on exhibit for the first time alongside other Mettler-Toledo x-ray systems, metal detectors, vision systems and checkweighers for bulk and packaged food and pharmaceutical products.

-

Learn the details behind an X-ray inspection system enabling a pet food provider to effectively inspect their products to identify and remove any that contain foreign objects.

-

Explore the core principles of due diligence, legal requirements and standards for food safety, and ways to reduce the risk of product recalls.

-

Food contamination with microbiological contamination can have disastrous consequences for consumers. Harsh cleaning regimens are often standard in food production environments to minimize the risk of bacterial infection. This webinar will outline how to protect your systems from bacterial contamination.

-

Mettler-Toledo Product Inspection is showcasing a wide range of stand-alone and fully-integrated automated smart product inspection systems at Interpack 2023. The advanced product inspection technologies on Booth A60 in Hall 11 are all designed to help food manufacturers boost productivity, increase product safety, protect brand reputation and reduce recalls. The full suite of technologies offers high-performance end-to-end inspection capabilities from ingredient stage to label verification.

-

Mettler-Toledo Product Inspection will host a live webinar on April 20th, 2023 at 1:00pm ET to provide guidance on how to validate, verify, and monitor conveyorized metal detection systems.

-

Product recalls can damage a company's reputation. Learn about the reasoning behind recalls, the impact of recalls, and what companies can do to minimize their exposure to such risks.

-

Live event scheduled March 9th 2023 will discuss the damaging nature of glass-in-glass contamination for food manufacturers and how x-ray inspection can help to mitigate these risk.

-

METTLER TOLEDO Product Inspection will demonstrate a variety of inspection systems for the meat and poultry industries in booth #C13131 at the International Poultry and Processing Expo, being held at Georgia World Congress Center in Atlanta, January 24-26, 2023.

-

We will demonstrate a variety of new inspection systems for the food and pharmaceutical industries in booth #S1714 at Pack Expo International, being held at McCormick Convention Center in Chicago, October 23-26, 2022.

-

METTLER TOLEDO Product Inspection will demonstrate a variety of inspection systems for the commercial baking industry in booth #3474 at IBIE, being held at the Las Vegas Convention Center, Sept 18-21, 2022.

-

Meat and convenience products processor installs x-ray inspection solution to satisfy increased customer requirements and demands in terms of quality assurance and production capacity.

-

A family-owned business that produces fruit spreads made from all-natural ingredients installs upgraded systems to ensure product accuracy, label printing, and tracking capabilities for their customers.

-

Read how a supplier of quick-service restaurants retrofitted its production lines with space-saving checkweighers and was able to achieve a higher throughput than ever before.

-

Here, a nut manufacturer finds a solution that allows them to detect contaminants in products packaged in aluminum foil and provides ease and flexibility in changing product types.

-

Realize the value of connectivity, and more specifically, the value of the information provided by checkweighing, metal detection, vision inspection, and X-ray inspection.

-

This guide provides you with the tools to evaluate the washdown capabilities of a given piece of production equipment.

-

Rapid progress being made and both yogurt production plants means manufacturers must modernized and upgraded to meet the demands of the consumer in the Greek and international markets. Read how one yogurt manufacturer ensures product safety and brand protection by detecting contaminants of various size and materials.

-

METTLER TOLEDO Product Inspection introduces several new technologies in booth C-1814 at Pack Expo, being held at the Las Vegas Convention Center, September 27 – 29, 2021.

-

METTLER TOLEDO Product Inspection will demonstrate a variety of inspection systems for food processing in booth #8003 at Process Expo, being held at McCormick Place Convention Center in Chicago, November 2 – 5, 2021. In addition, the company will have equipment on exhibit in Process Expo's Bakery Production Line.

-

Mettler-Toledo’s rapid Configure-to-Order (CTO) Quick Ship Program helps manufacturers to meet product demand

-

The new CM33 Washdown and CM35 Washdown combination systems are specifically designed to address the needs of manufacturers operating in harsh production environments that need both metal detection and checkweighing.

-

METTLER TOLEDO has launched a Quick Ship Program for some of its popular checkweighing and x-ray inspection equipment to speed up delivery lead times to its customers.

-

To help manufacturers access expert advice to select the right inspection equipment for their products, METTLER TOLEDO Product Inspection is providing free product evaluation and testing services.

-

Alongside weight monitoring, the checkweigher used at Protina Pharmazeutische GmbH offers other important functions that support the company's system of strict quality management.

-

Orthomol pharmazeutische Vertriebs GmbH develops and markets an extensive range of food supplements. Annually over 50 million pouches and 12 million drink bottles leave the premises. A new two-lane C35 AdvancedLine checkweigher excels in high weighing accuracy and throughput, and its versatile product handling features can be flexibly adapted to changing requirements in Orthomol's production lines.

-

Health Specialties Manufacturing produces probiotics, enzymes, vitamins and joint-muscle blends including liquid and powder blends and a variety of packaging sizes and formats. They installed an x-ray inspection system that ensures they protect product quality.

-

METTLER TOLEDO has launched a series of washdown resistant checkweighers for weighing applications in food manufacturing environments. The equipment is designed for use in areas with cleaning regimes that use caustic cleaning agents to combat bacterial contamination risks.

-

For one North American distillery, a strengthened product portfolio meant an increase in the number of packages being labelled. Existing quality inspections struggled to meet the required standards as product demand grew. CI-Vision provided vision inspection solutions to help achieve their high quality standards.

-

with each new release of the food safety standards, the auditing requirements become more stringent. Food processors don't just have to provide safe food, they have to prove that they can supply safe food. So how can a diligent food processor keep on top of the data that demonstrates their absolute commitment to food safety? This white paper looks at how the compilation and management of vital food safety data can be streamlined by the latest generation of data-management software.

-

Food and pharmaceutical manufacturers can still experience Mettler-Toledo Product Inspection’s newest technology innovations and glean industry insights that the company was going to present at Interpack 2020.

-

Incidents of physical contaminants in food can have a detrimental impact on brand reputation. This white paper explains different types of physical contamination in food and how to prevent them.

-

Tall, rigid containers — metal cans, doypacks, cartons, composite cans/tubes, and plastic and glass containers — are used extensively across the food industry. However, inspecting these types of packaging for physical contaminants and quality defects using x-ray inspection can prove challenging for numerous reasons. This white paper looks at the ability of x-ray technology to enhance food safety, quality control and operational efficiency.

-

In this white paper, we define package conformity and why it's important to food industry stakeholders. Further, we explore the technologies available to meet conformity objectives and how using them can benefit your business.

-

If your metal detector is not working to the optimum sensitivity specification, then metal contamination could be passing through your production line, undetected. This application note provides 5 steps to maximize the performance of your metal detector.

-

Different baby food and infant formula applications require distinct product inspection systems. Choosing the right machine to suit individual products and packaging types is crucial to ensure high levels of detection sensitivity and minimize false rejects. This white paper looks at the current marketplace and growth trends of the industry, and explores the many different inspection technologies available.

-

A major nutraceutical manufacturer proactively implemented a vision inspection program into their formula lines to ensure a safe and quality nutrient product for infant consumers. However manual inspection was creating a bigger range of tolerances than product specifications. Knowing their inspection needs and product specifications, CI-Vision was able to develop precise product tolerances with progressive technology that was able to capture defects, while pattern-matching algorithms would detect and reliably reject defective products from the production line.

-

Arevalo Foods produces more than 3.5 million tortillas per day at their state-of-the-art facility. To support their double digit growth over the past few years, they installed three metal detectors to help protect their final product quality.

-

The Jewel Date Company is in a sweet spot, with health-conscious consumers driving the popularity of dates as an alternative to refined sugar. To protect their product quality while meeting rising demand, they selected an advanced metal detector for one pipeline system and two conveyorized systems.

-

This paper is intended as a general guide on equipment safety, for users and suppliers of product inspection equipment. It should be thought of as a framework for discussion on the topic, assisting both users and suppliers in meeting their shared responsibility for equipment safety.

-

As manufacturing continues to become more globalized and the supply chain also becomes more unified, recalls of significant scale are likely to become more common.

-

We review the pros and cons of metal detection and x-ray inspection to help you decide which inspection technology to invest in to ensure the quality and safety of your products.

-

This white paper gives guidance on the essential processes of validation, verification, and routine performance monitoring for in-line product inspection equipment in food making facilities.

-

Our new GC Series conveyorized metal detection systemsaim to improve compliance and reduce total cost of ownership. The new systems support food and non-food manufacturers' quality and production objectives by providing robust, easy to use, modular equipment, which is readily re-configurable to support future requirements.

-

For a cheese maker with highly automated processes, a combo checkweigher and metal detector made the perfect tool for ensuring compliance with the HACCP regulations applicable to food production.

-

Ice cream manufacturers are looking for a better way to prevent labeling errors. After researching available options, one manufacturer decided to investigate vision inspection as a quality control solution.

-

To further reinforce positive customer experiences, an ice cream manufacturer challenged themselves to further minimize its already small risk of foreign body contamination by implementing x-ray inspection.

-

More than 200 million baked goods leave a bread manufacturer's plant annually. With such high volume, how does the company ensure its products meet the highest requirements of safety and quality?

-

Staying on top of technology in a competitive market makes Crofter's Foods a leader in the organic and all natural food industries. Using the METTLER TOLEDO systems, Crofters is able to monitor and verify every product package meets their specifications and offer their customers the advanced tracking information they desire.

-

Metal detection is essential for SQF food safety certification, and checkweighing helps to reliably meet net weight. To support their needs, a chocolatier installed a combination checkweigher/metal detector.

-

This case study shows how Bell Food Group, the meat supplier for an international fast food chain, uses X-Ray inspection to ensure burger patties are contaminant free and are of the highest quality.

-

This article covers five key inspection challenges meat and poultry manufacturers face, how they can overcome those challenges, and how they can enhance their production lines.

-

To get the most out of your metal detection program, it’s important to understand the factors that affect metal detector sensitivity and the ability to find different types of metal. This guide explains the various elements.

-

This spice manufacturer faced a challenge of having to manually lay down larger boxes prior to going through the metal detector. A solution with a tall aperture allowed them to eliminate this step and set up a fully automated packaging line.

-

In this paper, we explain the differences between validation, verification and routine performance monitoring and give an overview of recommended test methods for different metal detection systems.

-

Glass is often the preferred packaging material for food manufacturers. However, checking for foreign bodies in a finished pack is critical, as just one glass shard can have catastrophic consequences.

-

The white paper explains the importance of identifying foreign body contaminants in food and can be used as a checklist to evaluate the various metal detectors and x-ray inspection systems on the market.

-

There are an increasing number of ways in which a label might now fail to meet one of those specifications, making a strict label quality control process more necessary than ever.

-

This white paper explains how vision inspection systems help prevent recalls and protect brand reputations.

-

The unique characteristics of your ice cream products present inspection challenges. Fortunately, there are solutions available to address your specific challenges.

-

The unique characteristics of pet food products present inspection challenges. Fortunately, there are solutions available to address your specific challenges.

-

The unique characteristics of yogurt and other dairy products present inspection challenges. Fortunately, there are solutions available to address your specific challenges.

-

The Product Inspection Group of METTLER TOLEDO, the largest manufacturer of product inspection systems for the food and pharmaceutical industries, is hosting a Grand Opening event for their customers and trade media on July 12 – 13th, 2018.

-

J.O. Spice Company is a family-owned manufacturer of crab and seafood seasonings. At their start in 1945, the original husband-and-wife team commercialized recipes that were handed down through generations.

-

This white paper explains why the hygienic design of product inspection equipment is critical, the key benefits of investing in such equipment, and how it helps ensure food safety.

-

This white paper explores common filling problems, shows applications and methods of controlling filling processes, and provides calculations showing savings checkweighers can achieve.

-

This white paper takes a thorough look at HACCP and HARPC and details their similarities and differences. It also explains key steps food companies must take to transition from HACCP to HARPC.

-

This article explains how a variety of product inspection equipment on the production line increases confidence that due diligence has been taken to ensure product quality.

-

This condensed version of the Industry 4.0 Guide provides an improved appreciation of Industry 4.0, guidance integrating product inspection equipment with Industry 4.0 practices and innovations.

-

Metal detection and x-ray systems specifically designed for pumped products in addition to checkweighers and vision equipment ensure perfect packaging and labeling every time.

-

Food safety and quality is paramount. Because of this, La Provence Bakery needed new inspection equipment to maximize final product quality after installing a new cookie line.

-

Oakshire Mushroom Farm needed new metal detectors to accommodate rising demand. This article explains the selection process and how the technoloy improved food safety and final product quality.

-

X36 Optimizes Detection Sensitivity in Bulk Flow Products While Maximizing Productivity

-

As food and pharmaceutical manufacturers strive to ensure maximum efficiency on their processing lines to maintain competitiveness, the X36 x-ray inspection Series from Mettler-Toledo Safeline X-ray can help. This series of adaptable x-ray inspection systems uses the most advanced imaging technology on the market to provide high-detection sensitivity appropriate to a broad range of packaged applications.

-

New food x-ray systems for tall, rigid containers ensure maximum detection sensitivity and high throughputs while reducing operational costs

-

Mettler-Toledo Safeline’s new range of HDS Pipeline Metal Detectors is developed specifically for use on vacuum filling lines for detection sensitivity and stability, as well as user-friendly operation in potentially harsh or extreme working environments.

-

This white paper looks at the most common food safety standards, their latest requirements, and explains how a product inspection program can help food manufacturers meet these requirements.

-

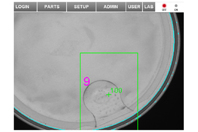

A properly calibrated vision inspection system can spot container defects before filling, preventing contamination and spillage, reducing waste, and improving standards compliance.

-

Quality control is one of the most important stages of the production process. Implementing a quality control program with automated vision inspection helps ensure every product meets quality standards.

-

This white paper focuses on bulk foods applications, discusses why manufacturers submit bulk foods to product inspection and explores what inspection technologies can be used.

-

Amway's success is driven by relationships and maintaining high-quality products. To ensure continued success, Amway installed x-ray inspection systems and checkweighers at its food manufacturing facility.

-

When Key Ingredient Market expanded operations, it needed new equipment. With quality as its backbone, this case study explains why metal detection was a key part of the company's success.

-

This white paper explores the ways in which technology and communications languages have evolved in order to address industry-wide challenges.

-

If production equipment fails, manufacturers face unplanned downtime, reduced output, and lost revenues. This article explains how preventive maintenance reduces the risk of unplanned downtime.

-

For specialty desserts, maximum product quality has to be guaranteed. High-precision checkweighing and metal detection systems are essential in achieving the highest quality.

-

While checkweighers are often associated with compliance to regulations, they also boost your bottom line through the reduction of waste, tightening of tolerances, and helping to produce more consistent products. Checkweighers provide an immediate positive contribution to productivity and profits with most systems paying for themselves in a matter of a few months, weeks, or even days! Here are 10 reasons your company should invest in checkweighing technology.

-

Metal detector sensitivity performance is usually expressed in terms of the diameter of a test sphere made from a specific type of metal, such as ferrous, non-ferrous, aluminum or stainless steel.

-

This paper explains how product inspection systems support food safety compliance by eliminating physical contaminants and the factors that affect the sensitivity of product inspection equipment.

-

METTLER TOLEDO joins the Organization for Machine Automation and Control (OMAC) and is committed to producing PackML-enabled equipment. PackML, Packaging Machine Language, and related calculations enable production line performance improvements.

-

‘Product effect’ (a phenomenon where the type of product being inspected can itself hinder the inspection technology’s capability to identify a particular contaminant) has long been a problem for food manufacturers. In the case of metal detection, product effect can be caused by a number of factors such as high moisture or salt content, temperature variations, size and shape of the product, orientation through the detector and packaging material.

-

The METTLER TOLEDO Product Inspection Division announced today that it will be building a new state-of-the-art facility to accommodate the growth of its business throughout the Americas. The new facility is expected to be completed in late 2017, and will be located 15 miles north of the Division's current site in Tampa, FL, which houses the company's Safeline Metal Detection and X-ray Inspection businesses. It will also become the home of the Hi-Speed Checkweighing business, which is planned to relocate from Ithaca, New York during the course of 2018.

-

Considering TCO helps to understand better the costs over and above the purchase price and also – when suppliers have differing offers – to compare them and ultimately to substantiate the investment decision.

-

To ensure that the highest quality levels are preserved at all times, Germany-based Koenig Backmittel processes only the very best raw ingredients, whilst also placing great importance on its state-of-the-art production technology. As part of its incoming goods checks for hazelnuts, an x-ray inspection system inspects the raw ingredients for contaminants to provide a significant part of the overall quality management process. This helps ensure the company follows through on one of its guiding principles, “Quality Ensures Success.”