Protecting Manufacturers Against Recalls - Seal Verification For Infant Formula Containers

In the nutraceutical manufacturing environment, product contamination can lead to product recalls and devastating consumer harm. Without proper quality assurance, a manufacturer's bottom line could be drastically affected by defective product reaching and potentially harming an infant consumer.

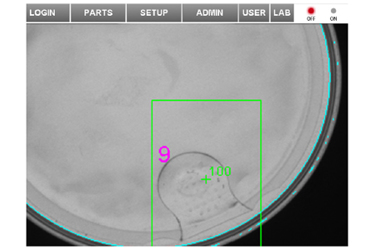

In order to prevent these threats, a major nutraceutical manufacturer proactively implemented a vision inspection program into their formula lines to ensure a safe and quality nutrient product for infant consumers. As a strict industry standard, quality assurance programs must be put into place, however manual inspection was creating a bigger range of tolerances than product specifications. The manufacturer required the most accurate inspection solution possible – to detect the smallest of defects in the container's foil seals, that could lead to dangerous contamination and product spoilage.

Knowing their inspection needs and product specifications, CI-Vision was able to develop precise product tolerances with progressive technology that was able to capture defects, while pattern-matching algorithms would detect and reliably reject defective products from the production line.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Food Online? Subscribe today.