FOOD SAFETY SOFTWARE CASE STUDIES

-

Hillshire Brands Uses Manufacturing Intelligence

Explore solutions utilized by the Jimmy Dean brand, part of the Hillshire Brands portfolio, to address weight variance in one-pound sausage rolls that was driving up product giveaway and lost revenue.

-

Increase Production Capacity With Virtualized Process Automation

Learn how Sleeman Breweries grew their production, improved process control, and avoided the high expense of building a new greenfield facility.

-

Full Sail Brewing Taps Manufacturing Intelligence To Enhance Process

Learn how a new filtration process helped Full Sail Brewing Company use water more efficiently while creating less waste and helping preserve a unique employee culture.

-

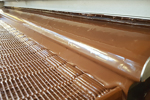

Solution Helps Chocolate Manufacturer Build A Streamlined Factory

Chocolates Valor S.A. produces high-quality chocolate bars, chocolates and snacks. The company invested in digitalization solutions for the production environment, in particular through Preactor APS, which is a family of products for production planning and programming that improves the synchronization of manufacturing processes and offers greater visibility and control. It showed an immediate return on investment.

-

Brand Spirits Leader Digitizes Business Operations With The SIMATIC IT Suite

Gruppo Campari closed 26 acquisitions in the spirits industry in the past two decades to become the world’s sixth player, with over 50 premium and super-premium brands. With each acquisition, Gruppo Campari needs to integrate new products, plants and assets into its operations management systems. By 2012 they realized there was no standard workflow for document authoring and validation, and information was shared via email or phone. Using Siemens technology, Gruppo Campari has created a unified repository for all product specifications and increased the efficiency of product development and manufacturing processes.

FOOD SAFETY SOFTWARE WHITE PAPERS & ARTICLES

-

Rethink What You Should Expect From Your System: Modern Batch Solution

Today’s dynamic manufacturing climate presents multiple challenges, forcing manufacturers to compare traditional and modern batch and rethink what to expect when choosing a system.

-

How Real-Time Data Analytics Powers Enterprise Agility

Successful business systems analyst managers must supply executives with real-time data to bridge the gap between enterprise resource planning (ERP) and operational data. When all these data points are tied into an enterprise-level dashboard, such as a unified operations center, decision-makers have instant access to a wide array of vital metrics.

-

Optimizing Food And Beverage Production Processes With Data

Data is the key to unlocking the insights to address these challenges, but it’s not enough just to collect data. A robust operational data management solution and platform is pivotal to harnessing the massive amounts of data generated within food and beverage plants.

-

Condition Monitoring In Consumer Products Plants

Now is the time to start your IoT journey. The trend toward digitalization of the world’s industrial plant facilities is already in motion and companies must get started quickly to remain profitable and competitive. Now operators can connect, collect and analyze data from aging as well as leading infrastructures to immediately monitor machines in one centralized location.

-

Digitalization – Unlocking Unlimited Potential For Consumer Products Companies

To get a product into consumers’ shopping baskets, companies must pay strict attention to everything from the recipes for their products and where materials are sourced, to working conditions and purpose driven marketing, all while introducing new consumer preferred products to the market faster than ever before.

-

Adapting To New Consumer Habits In The Wake Of Coronavirus

As the coronavirus pandemic wreaks havoc on industries across the globe, consumers are drastically changing their habits. The shakeup has been especially pronounced in the food sector, where in-person shopping is no longer being done as frequently and groceries are increasingly being ordered for delivery. Food producers are making aggressive changes to adapt to the new landscape. Remote monitoring and analytics provide the tools necessary to stay ahead of the curve.

FOOD SAFETY SOFTWARE PRODUCTS

-

Say goodbye to paper and manual spreadsheets and hello to maximum efficiency, productivity, and visibility! Plex MES is the only single-instance, multi-tenant cloud-based SaaS production platform that operates at scale. This allows for a common production ecosystem that supports a real-time, single source of data. It can tie production and inventory to quality with end-to-end, detailed traceability. With Plex, you can connect people and systems, automate processes, track data from end to end, and capture and analyze information like never before.

-

A main factor in increasing production efficiency is a regular and exact analysis of all available production data. This is especially true in large factories and multi-site operations that are dependent on a flexible, web-based quality data management system like Comscale4, the system provided by WIPOTEC-OCS.

-

Health-conscious consumers are changing the way they think about their food. Not only do they want high-quality ingredients. They also want assurance that the entire production process is safe and compliant with regulations. Not meeting these demands can harm brand values. Our solutions provide a holistic view into product and production information, including the full supply chain, and specifically address compliance management and the handling of complex change procedures.

-

The Palltronic Compact Touch Integrity Test Device is the next generation of pressure decay integrity test device, designed specifically for Food & Beverage producers.

-

FactoryTalk® CPGSuite is an MES solution designed specifically for the Consumer Packaged Goods industry. CPGSuite provides scalable, value-based applications to help you achieve operational excellence, increase the effectiveness of your supply chain, adhere to regulatory compliance guidelines, and meet your sustainability goals.

-

Generic ERPs are a poor fit for food manufacturers. With no specific industry focus, implementation times are frustratingly slow and extensive customizations are almost always required. JustFood ERP solves this problem with a system focused on recipe-based manufacturing. This laser focus allows companies to spend less time struggling to make the system work for them and instead devote all their energy to prioritizing the production process, quality management, and the other differentiators that lead to growth.

-

Increasing yield while maintaining a flexible line is seen as a contradiction to some food manufacturers. Our automation technology offers a balanced solution for increased productivity and profitability.

-

Document your production and control your product inspection devices with data management software ProdX.

FOOD SAFETY SOFTWARE MULTIMEDIA

-

See how Rockwell Automation can harness your data to meet the operational challenges presented by a complex CPG industry.

-

Digitalization changes the way consumer products are bought, consumed and evaluated. Watch this webinar to learn how centralizing lab and quality management allows companies to close the quality loop from idea to shelf. You will learn how to increase lab efficiency, reduce time to result, enhance real-time management and provide automated guidance to lab scientists.

-

This animation explains how companies can combat industry disruption from new, innovative companies and business models in the food and beverage industry by adopting the digital enterprise. It's no secret that companies like Amazon, Blue Apron, HelloFresh, and more are changing the way consumers and consumer packaged goods companies relate. This video shares how companies can become more innovative and agile to compete with these challengers through the value of digitalization, and provides an example of what a digital food and beverage company looks like.