Pipeline X-Ray Inspection Systems Of Pumped Food Products

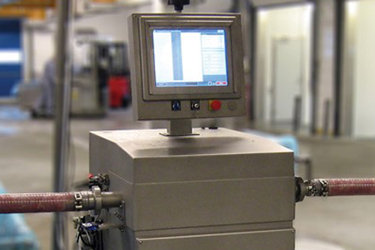

METTLER TOLEDO Safeline provides pipeline x-ray inspection solutions that are specifically designed to inspect pumped food products such as meat and poultry as well as slurries, semi-solids and fluids, at any stage in processing or before final packaging. Applications typically include sauces, jams, minced meat, molten chocolate and dairy spreads, as well as products that cannot be sieved - for example, textured fruit purées and yoghurts containing fruit chunks.

Pipeline x-ray equipment delivers superior product safety for pumped food products through the detection and removal of physical contaminants such as glass, metal, mineral stone, calcified bone and high density plastic in the early stages of production. High accuracy x-ray inspection technology minimizes the risk of product recalls, protects consumers from harm and safeguards brand reputation.

METTLER TOLEDO Safeline’s pipeline x-ray equipment offers high throughput, automatic calibration and a hygienic design. Throughput for slurries, semi solids and fluids is up to 18 tons per hour while meat and poultry products can typically be inspected at around 9 tons per hour. Pipeline x-ray systems are designed to automatically adapt to changes in the product flow rate and can adjust the scan speed as well as the associated reject timing to align with the speed of the production line.