Optimize complex batching with multi-shaft mixing technology. Achieve rapid powder dispersion, uniform heating, and automated discharge for high-viscosity pastes and gels.

- Optimizing Mixing Efficiency: 5 Strategies For Industrial Manufacturers

- Product Inspection: Application Solution — Bulk Peanuts

- Understanding Modern Storage Tank Design And Fabrication

- Boost Data Center Cooling With Endress+Hauser's Instrumentation

- Reducing Complexity In Data Center Cooling Temperature Measurements

- Ensure Quality Control With Innovative Software

- Remote Monitoring And Control Solutions For Food Safety

FOOD MANUFACTURING GUEST CONTRIBUTORS

-

The EU's Ban On TiO2 In Food May Impact Pharma. Here's What You Should Know.

Titanium dioxide (TiO2) is used as a food additive and OSD pharmaceutical excipient. In 2020, the European Food Safety Authority noted data gaps regarding particle size, which can affect its toxicological properties, so the European Commission banned it as a food additive. Here's how this could impact pharma.

-

Implications Of The Upcoming USDA Strengthening Organic Enforcement Rule

The new Strengthening Organic Enforcement (SOE) Rule, which went into effect in March 2023, seeks to reduce fraud in the organic marketplace, improve the USDA’s enforcement protocols, and enhance oversight of organic producers, handlers, and certifiers. Though the rule will require action for many businesses and organizations, these changes will ultimately create a more unified, trusted, and transparent organic supply chain.

-

Addressing A Lack Of Transparency In Green Claims

The rise in consumer awareness and demand for greater transparency has led to changes in regulations worldwide. In response to greenwashing in the food sector, as well as other industries, regulatory authorities are stepping up efforts to hold organizations accountable for their green claims.

-

Smart Irrigation For Agriculture Leads To More Efficient Carbon Capture

Farmers are key to carbon capture, though many plans to reverse greenhouse gas emissions — such as the one described in Lawrence Livermore National Laboratory's 2020 report on California's efforts, Getting to Neutral — largely ignore them.

WHITE PAPERS

-

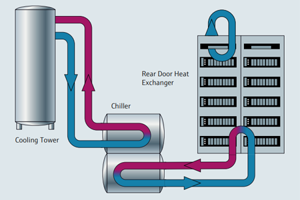

Reducing Complexity In Data Center Cooling Temperature Measurements7/22/2025

Endress+Hauser’s iTHERM SurfaceLine TM611 non-invasive temperature measurement performs comparably to traditional industrial thermometers with an elegant mechanical innovation.

Learn more about these advanced product inspection technologies like metal detectors, X-ray systems, and checkweighers that are revolutionizing food safety and compliance.

Explore the core principles of due diligence, legal requirements and standards for food safety, and ways to reduce the risk of product recalls.

Today’s dynamic manufacturing climate presents multiple challenges, forcing manufacturers to compare traditional and modern batch and rethink what to expect when choosing a system.

Product recalls can damage a company's reputation. Learn about the reasoning behind recalls, the impact of recalls, and what companies can do to minimize their exposure to such risks.

APPLICATION NOTES & CASE STUDIES

-

Optimizing Mixing Efficiency: 5 Strategies For Industrial Manufacturers2/6/2026

Enhance production efficiency by aligning mixing technology with material viscosity. Implement automated controls and advanced powder injection to reduce errors and energy costs.

FOOD ONLINE CONTENT COLLECTIONS

In this free collection of articles, you’ll find articles on four different types of inspection systems and how they work to keep food safe. Further, these articles will explain the creation of food safety and quality programs and how the four types of technology are used to bolster these programs.

More Content CollectionsLATEST FOOD HEADLINES

- MyLand Partners With Growers Edge To Introduce Performance-Backed Model For Specialty Crops

- AERZEN At IFAT 2026

- Transforming Africa's Future Farmers: Satellite-Enabled IoT Powers Data-Driven Agribusinesses

- Rice Stink Bug Genetic Mapping Offers Clues To Curb Costly Crop Pest

- Rice Gene Discovery Could Cut Fertiliser Use While Protecting Yields

WEBINARS

- The Critical Role Of Product Inspection Systems In Manufacturing

- Ensuring Food Manufacturing Quality Assurance With Reject Devices

- The Significance Of Preventive Maintenance For Product Inspection Systems

- Raw Material Product Inspection: Are You Missing This Important Stage?

- Overcoming Key Inspection Challenges For Quick-Prep Foods And Meal Kits

FOOD INDUSTRY INSIGHTS

-

Achieve seamless scale-up and process versatility by utilizing multi-shaft mixing technology. Balance high-shear dispersion with vacuum integration to optimize complex formulations.

-

Industries rely on advanced storage tanks and pressure vessels to safely manage liquids, gases, and powders. Discover how custom-engineered solutions can enhance efficiency, safety, and compliance.

-

Major retailers are mandating x-ray inspection for their suppliers. Uncover why this technology is crucial, and its capabilities beyond contamination detection to encompass vital quality and integrity checks.

-

Prioritizing pet safety and quality is paramount in pet food production. Explore essential solutions for four key production stages, ensuring safety, compliance, and brand integrity.

-

In today's fast-paced production, precision checkweighing is crucial. Discover how smart algorithms, real-time analysis, and automation optimize performance and minimize downtime.