ABOUT US

Ross serves the requirements of the Food Industry, in virtually every industrialized country around the world. We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match. In the USA alone, we operate five plants, an analytical laboratory and a vigorous R&D program. Overseas, Ross equipment is being built in our own factories in China and India, and manufactured under license in other counties. Typical applications include mixing, blending, particle size reduction, emulsification, homogenization, powder induction, vacuum processing and more.

Specifications that define a mixer built for a food industry application reflect a combination of industry standards, and the mixing functions needed for that particular application. A sub-micron emulsion, for example, requires high-shear agitation, vacuum and usually a heat-transfer system. The size of the mixer is determined by the throughput required. To guard against batch-to-batch contamination, CIP and SIP capabilities are available, along with such devices as air-purged seals and custom designed discharge valves. To ensure a high degree of repeatability, and to document the production of every batch, we often add a control system with data-logging capability.

The close connection between specific performance requirements and equipment features is the logical starting point for equipment design. But today, the challenge of specifying and designing a high-performance mixer is more than a two-dimensional process. We regularly address performance needs that are much broader than one particular mixing application. In fact, we often custom design equipment to meet production needs that have not yet been imagined.

CONTACT INFORMATION

Charles Ross and Son Company

710 Old Willets Path

Hauppauge, NY 11788

UNITED STATES

Phone: 631-234-0500

Fax: 631-234-0691

Contact: Sales

FEATURED ARTICLES

-

ROSS recently completed the largest Double Planetary Mixer in its US history, a Model DPM-750 capable of mixing up to an impressive 750 gallons per batch and engineered with safety features for a Class I, Division 1, Group D hazardous environment. This heavy-duty mixer delivers the robust agitation required for ultra-high viscosity materials while adhering to demanding safety standards.

-

Customizable ROSS Ribbon Blenders deliver reliable mixing of food, nutraceuticals, cosmetics, personal care products, in addition to chemicals, plastics, building materials and agricultural products.

-

A well-proven tool for robust mixing of high-viscosity materials, the ROSS Double Planetary Mixer delivers exceptional performance through its unique agitation system and adaptability, while meeting explosion-proof requirements. The Model DPM-150 is a heavy-duty mixer that can process formulations ranging from 20 to 150 gallons, with viscosities exceeding 6 million centipoise. It is one of several ROSS production models serving thousands of pharmaceutical, aerospace, adhesives, sealants, composites, and specialty chemical manufacturing plants around the world.

-

Engineered for applications requiring advanced mixing capabilities, the ROSS VMC-300 combines three independently driven agitation systems in one unit. This multi-shaft mixer integrates anchor, high-speed disperser, and axial flow turbine technologies to effectively manage complex and viscous formulations in the pharmaceutical, food, cosmetic, coatings, adhesives, composites, and other specialty chemical industries.

-

Industries rely on advanced storage tanks and pressure vessels to safely manage liquids, gases, and powders. Discover how custom-engineered solutions can enhance efficiency, safety, and compliance.

-

ROSS is pleased to announce the completion of a custom Coaxial Mixer. Through an innovative concentric-shaft configuration, this advanced system effectively blends, disperses, and homogenizes materials by combining two synergistic agitation technologies. In a variety of industries, such as adhesives, sealants, coatings, composites, cosmetics, and pharmaceuticals, the coaxial design enables processors to handle a wide range of rheologies while offering a range of different flow patterns.

-

Ross Mixers offers refurbished equipment through its factory reconditioning program.This initiative allows customers to purchase mixers that have been meticulously restored to "like-new" condition by the company's original equipment manufacturer (OEM) team.The reconditioning process includes thorough inspection, repair, re-polishing, and testing of all components to ensure optimal performance.

-

ROSS is pleased to announce significant price reductions on the Series 100 and Series 500 Production Batch High Shear Mixers.

-

The ROSS VersaMix VMC-320 is a versatile multi-shaft mixer for processing viscous solutions, offering powerful agitators, customizable controls, and semi-continuous operation with robust safety features.

-

ROSS Ribbon Blenders are used throughout the process industries for the efficient and effective mixing of powders, granules, pellets, grains and other bulk solids. Available in lab scale to full production models, these machines are built to handle a wide range of bulk densities and can be customized for heavy-duty and sanitary applications.

-

It is with great sadness that we announce the passing of Richard Ross, former president of Charles Ross & Son Company, on September 14, 2024. Rich was a visionary leader who played an instrumental role in shaping the company’s future and global success.

-

Built to handle a wide range of formulations and viscosities, the ROSS FDA-50 Fixed Tank Dual Shaft Mixer is a custom-design agitated pressure reactor ideal for processes that require meticulous control over mixing, temperature, and pressure in a compact and portable module. The stainless steel type 316 dished bottom vessel and removable dished cover can accommodate internal pressures up to 100 psi, stamped according to ASME Section VIII, Div. I.

-

ROSS Dual Shaft Mixers are versatile, robust and cost-effective systems engineered for accurate processing of high-performance formulations across a wide range of rheologies, solids loading, operating temperatures and pressures.

-

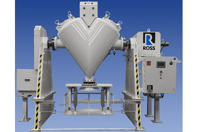

Offering a high level of precision and consistency, ROSS V Cone Blenders utilize diffusion as the main mechanism for mixing. As the V shaped vessel rotates on its horizontal axis, batch materials cascade down, distributing particles over a freshly exposed surface.