Understanding Particle Filtration In Liquids In Food And Beverage Industry Applications

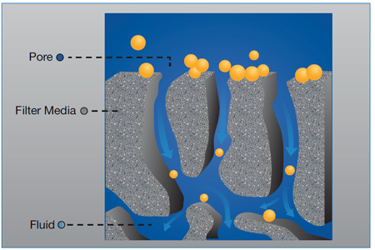

In food and beverage production there is often a need for particle removal filtration of liquids and gases, with the goal of achieving high product quality while driving down manufacturing costs. The purpose of this filtration is to remove undesired particles from a fluid to achieve a desired cleanliness level, prevent contaminants from entering a process fluid stream, or adsorb unwanted contaminants.

The proper selection of filtration equipment for particle removal is critical to achieving desired outcomes, while minimizing cost of ownership. There is a large variety of equipment available, ranging from relatively small direct flow filters, sometimes called “dead-end” filters, to crossflow filter systems and other systems for handling higher suspended solids loads.

Filters are available with many types of filtration materials, designs, performance characteristics, and separation mechanisms, so much so that their proper selection can seem daunting.

This article focuses on a narrower discussion about particle removal performance in liquids with cartridge and bag filters, i.e. in the microfiltration range of over 0.1 micron, and the filtration mechanisms involved.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Food Online? Subscribe today.