Maximize Food-Manufacturing And -Packaging Processes With Automated Machine Vision Systems

By Isaac Fletcher, contributing writer, Food Online

With the help of a machine vision system, food manufacturers can consistently produce high-quality products, enhance tracking and tracing, all while improve profit margins

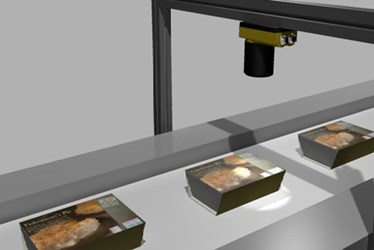

Within a food manufacturing operation, speed, efficiency, and quality are among top concerns for producers. When it comes to detecting and eliminating damaged goods, these concerns are as important as ever. By implementing a machine vision system, damaged products can be detected early on in the process. Since human inspectors simply do not have the ability to see all of the flawed products speeding past on a conveyor — often at speeds up to 500 parts per second — a machine vision system can be an essential part of optimizing any food production operation.

Planning Ahead

When installing any type of automated system, planning ahead is vital. By establishing a prioritized list of objectives and asking the right questions regarding a company’s unique needs, manufacturers can ensure that they achieve the most out of a vision system. What task needs to be performed? Is the system going to be used to ensure correct installation of components or that colors are of the right tone? How will the operating environment impact the system’s performance? Will the system be compatible with other third-party systems? Finding the answers to these questions will help ease the implementation process and ensure the system is used to its full potential.

Functionality

Machine vision systems function by shining light onto a target which is then reflected back to a camera. The image is then collected and the data is processed. After the image is processed to determine the measurements or other specifications of the product, the information is sent to a robot, or other automated system, that removes any product that does not fit the desired specifications. All of this is achieved within a split second as the production line continues moving. The components necessary for an effective vision system include proper lighting, lenses appropriate for the task at hand, and a camera to tie it all together.

Achieving Consistent Quality

With preset specifications afforded through the use of automated equipment, manufacturers can consistently produce high-quality goods. By using a machine vision system, variables such as length, height, and width can be easily controlled for, which establishes consistency throughout production. Additionally, vision systems can be used to confirm that the right amount of product is placed within a box or shipping container and can send error messages in the event the numbers are off.

Enhancing Tracking And Tracing

Vision systems are capable of serializing specific components, which makes the tasks of tracking and tracing more-readily achievable. In the event a consumer is not satisfied with a product, tracking and tracing can assist in detecting and analyzing any failures that may have occurred so they can be properly addressed.