Intralox Presents Proven Conveyance Solutions For The Poultry Industry At IPE 2009

Representatives from Intralox, L.L.C., will present their latest conveyance solutions to address key challenges in poultry industry applications in Booth #1658 at International Poultry Expo 2009, January 28-30, in Atlanta, Georgia. Intralox has long been a complete provider of conveyance solutions that increase productivity while reducing operational costs.

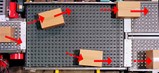

Specialized Case Conveyance

Intralox's Activated Roller Belt (ARB) technology provides a smart, automated method for directing the movement of conveyed articles. Proven successful at improving productivity, eliminating unnecessary labor costs, and reducing operational expenses in a variety of case handling applications, Intralox ARB solutions offer greater flexibility, reliability, and safety over alternative case handling options.

Superior Sanitation

Intralox SeamFree™ belts are designed to enhance sanitation efficiency by conserving the time and water used for sanitation. The belts' hinges open as they move around the sprocket, allowing for greater cleaning access to the belt interior, while the belts' patent-pending flume design effectively channels water and debris to the edge of the belt. When combined with the EZ Clean In Place (CIP) System and patented Angled EZ Clean Sprockets, poultry processors can achieve water and cleaning time savings of as much as 65%, compared to manual cleaning.

Spiral Solutions

Intralox's revolutionary line of Spiralox belting cuts product waste in half, eliminates metal wear debris, and reduces downtime for maintenance by up to 75%. Intralox spiral solutions safely convey poultry in cooling and freezing applications. Spiralox belting is available with a friction top surface for product alignment efficiency as well as with smaller openings for nuggets and other small food products.

SOURCE: Intralox