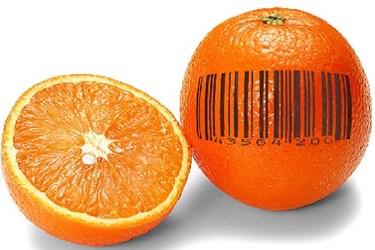

How Barcoding Is Helping Traceability In Fresh Foods

By Melissa Lind, contributing writer

Traceability and labeling requirements, combined with productivity needs in the fresh food industry, are making the use of advanced-labeling technology more attractive. The ability to accurately identify and trace product from farm to customer can be done more efficiently with barcodes than through any other means currently available.

The fresh food sector requires the ability to get products with short shelf-lives to market as quickly as possible in a cost-effective manner. Wholesalers and retailers who enjoy the benefits of barcoding used in other sectors are now demanding this technology be utilized for tracking fresh food. This demand, in addition to regulatory requirements and the passing of the Product Traceability Initiative (PTI), is forcing more processors to employ barcode and traceability technology.

Growers, processors, packers, and shippers can employ barcode technology for reporting production, inventory management, and traceability and verification purposes.

Growers

Implementing barcode technology in the field presents the greatest challenge. With dirt, moisture, lack of power sources, or digital communication signals, technology used in the field must be simple, robust and fast. Ideally, printing should be done as close to harvest as possible.

Some of these hurdles can be overcome with pre-printing at the plant, but this requires additional documentation, such as keeping a spreadsheet of what labels were printed with the ability to void non-used labels. If electricity and suitable weather protection is available, printing could be done with an on-site printer in a workstation with the elimination of the necessity of voiding as labels can be printed on-demand.

Related: Check out how mobile printing helped one pasta manufacturer

A third option is a mobile scanner and printer that allow direct printing of labels as cases are packed. Likely, the mobile equipment may rely on digital transmission, but data could be immediately incorporated into management of inventory, traceability, and shipment processes.

Processors, Packers, And Shippers

The packing or processing company that receives cases or cartons from growers may repackage them for shipment to end users. For this process, a more complex system is needed to track shipments in, transferring the contents, and shipments out. It must be capable of integrating information on cartons to reuse that information in palletizing, re-boxing, and mixing, along with inventory and shipping-process management.

There are two basic methods that are often employed — Lot Tracking and Carton Tracking.

Using the lot-tracking method is used more often, but it has drawbacks. As lots move through the supply chain, they may be separated and commingled with other lots. In the case of a recall, all the included lots would be considered contaminated. Consequently, a recall would be much larger and more expensive.

Carton tracking is more complex as the system identifies both the lot and the contents of each carton. If a specific lot recall is needed, the entire mix will not require recall. It does require more-advanced software, but the rewards are obvious.

In the case of processing, new lot numbers will also need to be assigned which track back to the original lots for visibility. In addition, the systems need to be fast and user-friendly, such as newer programs using touch-screen technology with automatic integration.

The use of scannable, barcode technology can make inventory-management systems much easier. Data from the farm to the processor/shipper can be automatically integrated and used for shipment management. Shipping manifests can include information from barcode labels right on the manifest. From there, the data can be checked both manually and verified electronically as products enter trucks and are delivered to customers.

The use of barcode is expected to grow with additional applications yet to come. Today’s consumer wants more information about their food and some companies in the food industry are already developing ways to get information directly to the consumer with smartphone technology.