Del Monte Increases Efficiency With Tray Pack/Shrink Wrap System

When Del Monte Foods eliminated its use of full wrap-around corrugated cartons to pack canned vegetables at their Mendota, IL, facility, the company installed Kisters Kayat's high-speed tray packing and shrink wrapping system — looking to increase productivity and reduce costs.

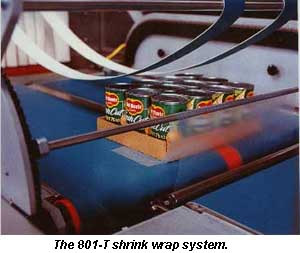

Kisters Kayat supplied Del Monte with a fully integrated line comprised of a TP-100 tray packer, tray turner, tray stacker, and 801-T shrink wrap system, which offered both quick product changeover and reliable performance.

"We switched from full cartons to shrink wrapped trays and cut our secondary packaging costs in half by reducing the amount of corrugated materials," noted Tex Hoopes, warehouse manager at Del Monte's Mendota plant. "We selected the Kisters Kayat system to maximize our throughput by matching our line speed requirements and reducing production line downtime."

The new system met the canned vegetable producer's requirements, packing more than 80 trays per minute. Del Monte typically produces 300 x 407 two piece steel cans on the production line and packs these 15.25 oz cans into 12-count trays that are double stacked and shrink wrapped as a 24-count bundle on the new equipment.

"We operate two 11-hour shifts during the peak packing season. In this environment, production line downtime has a direct affect on the total volume of product we can produce on that line," said Hoopes. "Since we installed the Kisters Kayat system, we've achieved more than 90% production efficiency on that part of the line at various times. As we progress on our learning curve, we expect that experience will continue to improve."

Kisters Kayat designed the continuous-motion 801-T shrink wrap system with a bottom overlap seal system that reduces routine maintenance and minimizes the downtime associated with moving parts. The system also creates a tightly wrapped final package that improves package appearance and package integrity. The result is an attractive multipack that enhances the visibility of the Del Monte label to promote the company's brand recognition.

The continuous-motion TP-100 tray packer features a tray blank infeed mechanism that utilizes a friction feed system that increases the capacity of the tray feeder while improving equipment reliability. Del Monte installed Kayat's optional extended tray blank magazine that holds up to 600 trays to further improve worker ergonomics. The system reduces operator involvement and lessens production downtime by reducing re-loading frequency of trays and assuring continuous performance.

Kisters Kayat Inc. offers a full range of shrink wrappers, tray-shrink packers and wraparound case/tray packers to customers in North and Latin American markets.

For more information contact Kister Kayat, Inc., 4100 U.S. Highway #1 South, Edgewater, FL 32141. Tel: 904-424-0101; Fax: 904-424-0266.