Automating Traceability Can Help Meet FSMA Requirements

By Isaac Fletcher, contributing writer, Food Online

Traceability and food safety go hand in hand, and in order to adhere to new food traceability requirements, food processors and manufacturers should consider automating their traceability systems.

Throughout the food processing and manufacturing industries, companies are working to prepare for coming FSMA changes. Although some changes will need to wait until laws come into full effect, companies can take action to begin addressing others now. One such area is traceability, and understanding how it will be regulated as FSMA laws come into practice.

In accordance with FSMA, food manufacturers will need to ensure that food products are traced from their origins, through the supply chain, and on to the consumer. The FDA is defining critical tracking events and other key data components for producers of all sizes. At each point along the supply chain, companies will be required to track and keep records for every unit of product.

FSMA, Traceability, And Electronic Recordkeeping: What You Need To Know

Although automating the traceability process is not required, it can make things easier for food companies. While the FDA has not mandated a particular automation technology for traceability purposes, automated track and trace systems are very effective in capturing necessary information and providing users with rapid access to records by reducing human error. The FDA aims to provide quick forensic traceability in the event that a food safety issue arises, and automation can help food manufacturers employ targeted recalls and enhance quality control throughout production.

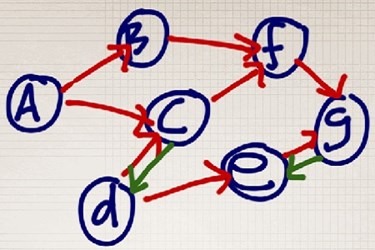

Traceability has been established as an important element in food production, and automated traceability systems already come in a variety of forms. Effective systems built on networked control systems and manufacturing information technology platforms are available in the marketplace and have seen widespread over the last 20 years. Although many options exist, manufacturers face the challenge of selecting the correct system for their respective operations, ensuring that the automated traceability technology is a good fit for the manufacturing environment.

A former food safety director explains why thorough traceability systems are crucial

To properly address the traceability requirements that come with FSMA, food manufacturers need to understand the challenges they face, address those challenges, and educate themselves on technology options that are available to further assist them. FSMA’s final rules will be in place before you know it. However, by considering automation and exploring the related technologies, companies can be fully prepared to elevate their traceability systems.