Waterproof Computers Withstand The Rigors Of Food Processing

By Isaac Fletcher, contributing writer, Food Online

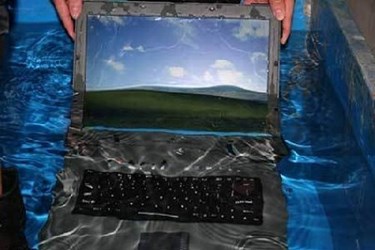

Food processors seeking a viable solution for computing in harsh environments may find an answer in the form of sealed, waterproof, industrial computers

A new line of stainless steel waterproof computers has been designed for food manufacturers to use in wet and dirty environments. The computers are also designed with resistance to airborne particles in mind. Primary applications for the waterproof units include dairy, produce, and beverage industries. The use of waterproof industrial computers in relevant processes can increase operational efficiency and provide cost savings to food processors and manufacturers.

Designed to achieve normal operation in harsh environments, such as those found in food processing, the waterproof computers can be placed in a production line, dirtied up from the process, and washed down at the end of the day just like the other equipment and machinery used during production. Because computers are a tool and vital component in production, allowing for them to be treated the same way as other equipment enables food processors to streamline care and maintenance while allowing for more rigorous handling.

The computers are made with cables that can be hosed down and treated with cleaning agents on a regular basis, which saves time and money that would otherwise be spent carefully cleaning around the components or replacing damaged parts. Additionally, the computers are manufactured with an anti-vibration hard drive and a wide operational temperature range to withstand the various rigors of production lines, such as vibrations from machinery and high temperature wash-downs and processes. Touch screens made with tempered glass and sealed with rubber gaskets provide increased resilience to these harsh operating environments.

Learn how Clean-In-Place is used to maintain sanitary conditions in food processing

Not only are the computers durable, the sealed, waterproof exterior protects the high end technology inside that allows food processors to meet computing needs. With local area network (LAN), wireless LAN, and Bluetooth options, connectivity is not an issue and food processors can choose a mode that best fits their unique production line. Furthermore, the computer requires relatively low power consumption which, coupled with the fan-less computer design, means the overall energy consumption is minimized.

With growing concerns over sustainability and energy usage, reducing the levels of energy needed for a process is becoming ever more important for food processors. Low-energy computers provide yet another avenue through which food production firms can transform old practices into more eco-friendly, sustainable processes and reap the accompanying financial rewards.