NETZSCH's Revolutionary All-Metal TORNADO T2 Rotary Lobe Pump – Ideal For Hygienic Processing Of Food Industry Products

Self-priming, valve-less, positive displacement pump ideal for any kind of liquid

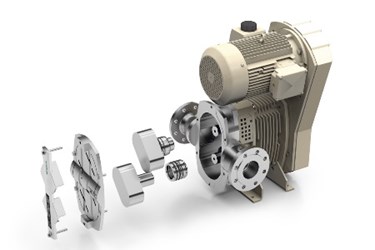

NETZSCH Pumps North America, LLC, experts in solutions designed specifically for difficult pumping applications, announces its All-Metal TORNADO T2 rotary lobe pump. With low pulsation and wear, the TORNADO T2 is available in a variety of sizes ideal for food industry applications. The All-Metal TORNADO T2 conforms with food safety and FDA food processing requirements stipulating that all metallic pump components coming into contact with the delivery medium are made of stainless-steel and offers a high-quality pump solution for sanitary processes.

The TORNADO T2 features a maintenance-friendly design, with no need to dismantle pipework or disconnect the drive for servicing. Physical separation of the pump head and bearing housing improves uptime, and the pump’s small footprint improves site utilization.

The rotary lobe pumps are ideal for meeting the need for hygienic processing of sensitive food industry products. The pump is available in a variety of sizes delivering quantities of 2,113-36,980 gallons per hour (gph), or 8-140 cubic meters per hour (m³/h). The smallest model is best suited for the flexible filling of edible oil.

Offering maximum operational performance, high reliability and durability, ease of maintenance, and a low total life cycle cost, the TORNADO T2 pump can be used for almost any media on intermittent, continuous or metering applications. The self-priming, valve-less, positive displacement pump is ideal for food industry applications and can handle any kind of liquid, including media containing gas, solids or fibrous matter.

The TORNADO T2 pump’s revolutionary design has been completely reengineered to maximize uptime. The pump’s all-metal design eliminates the excess wear and heat generated from the elastomer-to-elastomer contact found in other rotary lobe pumps. The torsional strength and deflection-resistant, shaft material combined with sealed-for-life, angular contact ball bearings ensure axial and radial shaft stability. This world-class stability maintains tolerances and stabilizes the pump against higher pressures.

The pump’s innovative design improves access for inspection, cleaning, service, and replacing parts, providing for FISP (full-service-in-place). Simply removing the cover plate on the TORNADO T2 allows quick and easy access to the pump chamber. The rotors are not bolted or keyed to the shafts inside the pump head and can be removed and replaced easily and quickly without the need for special tools.

Rotor synchronization is achieved with a setting device included as an integral part of the pump front cover. The pre-set cartridge mechanical seals are fitted directly into the rotor and mounted on the shafts as one assembly.

The revolutionary design enhances process efficiency with the smallest footprint by incorporating an innovative timing tooth belt to both synchronize and drive the pump’s rotating element. By reducing space required for pump installation and servicing, the pump improves overall site utilization.

About NETZSCH Pumps & Systems

NETZSCH Pumps & Systems has served markets worldwide for more than 60 years, providing customized, sophisticated solutions for applications in every industry type. Experts in solutions designed specifically for difficult pumping applications, NETZSCH supplies NEMO progressive cavity pumps, TORNADO rotary lobe pumps, and NOTOS multi screw pumps, as well as grinding machines, barrel emptying units, dosing technology and accessories. With a workforce of more than 2,000, NETZSCH Pumps & Systems is the largest business unit in the NETZSCH Group, with annual sales of more than 250 million Euros during the 2015 fiscal year.

Source: NETZSCH Pumps & Systems