Moisture-Absorbent Vacuum Packaging Gives Cut Fruits, Veggies Long Life

Carolina Fresh-Cuts is a Charleston, SC-based processor and packager of a broad array of fresh-cut fruits and vegetables. In all, the company's products comprise about 600 items ranging from sliced lemons and limes, chunked melons and peeled oranges to shredded cabbage, carrot and celery sticks, sliced mushrooms, diced onions and sliced or diced tomatoes.

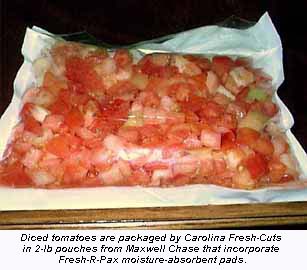

Operating out of a single plant, the company pumps out about 15,000-lb of product per day for distribution to foodservice, institutional and retail outlets in the Charleston area. A key component in Carolina Fresh-Cuts' successful marketing of value-added fresh-cut fruits and vegetables is its packaging — Fresh-R-Pax absorbent pads, pouches and trays from Maxwell Chase Technologies (Douglasville, GA).

Based on unique, patented technology, the packaging can accommodate vacuumization and optional gas-flushing and can be customized to meet the specific absorbency needs of individual products (including fresh meats). The proprietary absorbent material, which is GRAS (generally recognized as safe by the Food and Drug Administration), captures and retains excess moisture within the food package and gels the fluid without drying out the food.

Along with moisture, food-spoilage organisms are drawn into the absorbent material. The gelling action restricts the ability of these organisms to reproduce and contaminate product surfaces. As an example, according to Maxwell Chase spec sheets, the Fresh-R-Pax technology has been found to reduce aerobic organism counts on fresh and marinated poultry to 1/200th or 0.5% of normal levels.

As Tom Gautreaux, national sales director for Maxwell Chase, points out, "Cut fruits can be a little more challenging than cut vegetables in terms of extending shelf life. But still the Fresh-R-Pax system can double expected shelf life for many cut fruits. A very important factor is to ensure that the fruit is not over-ripe when cut."

Tomatoes Pose Challenge

"Tomatoes also present some special challenges due to their high moisture, but we have worked two years to perfect cut-tomato applications," says Gautreaux. He says the target shelf life that fast-food operators want for sliced or diced tomatoes is about 10 to 12 days. Processors who are experienced with the Fresh-R-Pax system can routinely provide 12 to 15 days shelf life for cut tomatoes.

"From our studies, we have found that a film pouch with an oxygen transmission rate (OTR) of 120 and an absorbent pad on one wall of the pouch performs extremely well for diced tomatoes," says Gautreaux. He adds that trays with padded drain cavities thermoformed into the base and heat-sealed with 120 OTR film perform well for sliced tomatoes. "It just depends on the product format, volumes and package dimensions the user is looking for," notes Gautreaux.

Jack Strobel is chief operating officer at Carolina Fresh-Cuts. When asked whether use of the Fresh-R-Pax pads, pouches and trays required any special adjustments in Carolina Fresh-Cuts' packaging line operations, Strobel said only minor adjustments were needed.

"We use vacuum packaging equipment from M-Tek Inc. (Elgin, IL). We like it because it gives us the versatility and multi-functionality we need to package all these hundreds of items," says Strobel.

Strobel adds that Carolina Fresh-Cuts does not flush the packages with any gases. "We don't feel we need to. In fact, in some cases, the addition of a gas blend may have some slight effect on product flavor," says Strobel. "Modifying the atmosphere with a backflush of gas could give our products a little more shelf life. But we don't think we really need it because we pack everything in five-pound volumes, which are quickly used up in most operations once opened."

Strobel continues, "So if a restaurant orders, for example, 100 pounds of diced tomatoes from us, the establishment gets 20 five-pound packages. The refrigerated, unopened packs have an easy five to six days of shelf life without a gas flush."

Moreover, the fresh-cut fruit and vegetable producer offers just-in-time delivery to its customers. "Each of our customers is visited three days per week," boasts Strobel.

Range of Applications

Besides fresh-cut tomatoes and fruit, other produce applications for which Fresh-R-Pax absorbent pads, pouches and trays are suitable include: fresh-cut red and green peppers, fresh-cut onions, fresh herbs, fresh-cut salads and fresh salsas.

Some examples of packaging applications for fresh poultry and meat include:

• Fresh tray packs.

• Modified atmosphere packs for foodservice and retail.

• Fresh marinated packs, including trays and foodservice supply.

• Bulk packs such as tubs and cartons.

For more information about Fresh-R-Pax packaging: Tom Gautreaux, Maxwell Chase Technologies, Tel: 404-351-3139.

For foodservice, institutional and retail market operators in the Southeast Carolinas area interested in fresh-cut fruits and vegetables: Jack Strobel, Carolina Fresh-Cuts, Tel: 843-747-7030.

For more information about M-Tek vacuum packaging equipment, Tel: 847-741-3500.

About the Author: Judy Rice has been writing about the food and beverage industries for more than 20 years. She worked as the packaging editor for Food Processing magazine for more than 15 years. Prior to that, she worked at USDA's Food & Nutrition Service for seven years. She currently freelances for a range of trade publications and is a regular contributor to Packaging Network and other VerticalNet Inc. websites. She is based in Lac du Flambeau, WI.